A practical guide from JIALONG Technology to help you clarify misconceptions and build a solid business case for upgrading your production.

Concern #1: “The upfront cost is prohibitive. We simply can’t afford a massive overhaul.”

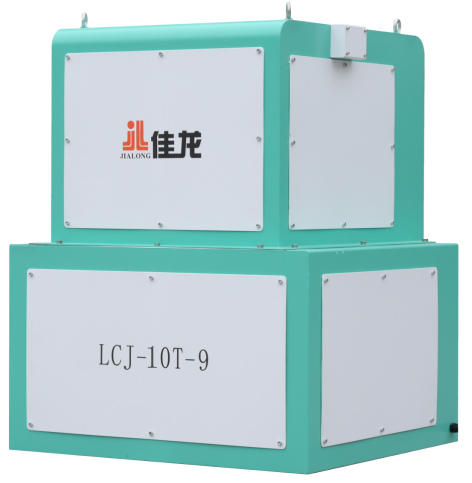

Optimizing Labor: One automated station can perform the work of multiple employees per shift, leading to direct and significant savings on wages and associated overheads. Maximizing Material Usage: Our high-accuracy weighing and filling systems drastically reduce product giveaway, ensuring raw materials end up in the final product, not as waste. This precision translates directly into healthier profit margins. Creating Scalable Solutions: We are experts in phased implementation. You can begin with a single machine to solve your most critical bottleneck. Later, as your business and budget grow, you can add more modules to build out a more comprehensive line. This dddhhhpay-as-you-growdddhhh model makes powerful automation accessible to companies of all sizes.

Concern #2: “My team will struggle with complex technology. It’s easier to stick with what we know.”

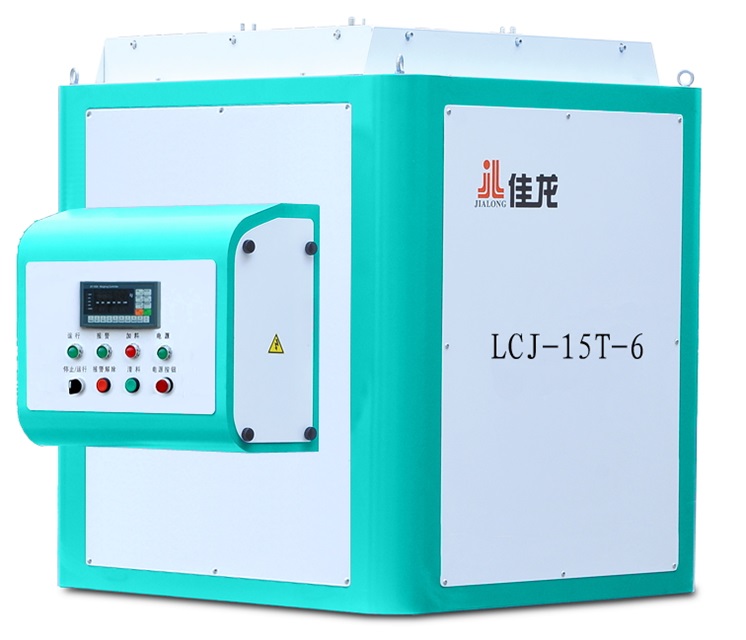

Intuitive Operator Interfaces: We equip our machines with large, graphical touch-screen panels. With clear icons and simple menus in multiple languages, operators can manage settings, run diagnostics, and monitor production with minimal training—often in less than a day. Comprehensive Knowledge Transfer: Our service extends far beyond installation. JIALONG’s technical experts provide thorough on-site training for your operators and maintenance staff. We ensure your team not only knows how to run the equipment but also understands why certain procedures are important, fostering a sense of ownership and competence. We see your team as a key asset, and our goal is to enhance their skills.

Concern #3: “The long-term maintenance is a hidden cost, and any downtime will be catastrophic.”

Built to Last: Dependability starts with quality components. We build our systems using proven, world-class parts from trusted brands like Siemens and Schneider Electric. This commitment to quality, combined with our robust engineering, minimizes unexpected failures and extends the operational life of your investment. A Partnership in Uptime: We understand that when you need support, you need it now. Our service infrastructure is designed for rapid response. With a deep inventory of spare parts and a network of skilled field technicians, we are structured to resolve issues quickly and efficiently, safeguarding your production schedule and providing you with critical peace of mind.